Monolayer and Continuous MoS2 Film on SiO2/Si wafer

Size:10mm*10mm (Sale!)

Buy NowSpecifications

1. The monolayer and continuous MoS2 come from the isolated MoS2 flakes. The flakes continue to grow bigger and then form the continuous film.

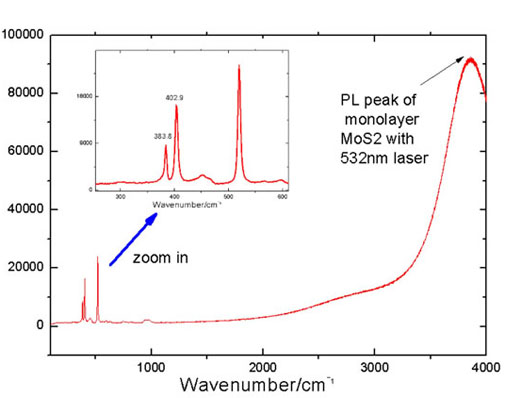

2. The monolayer rate is over 95%, and show very good PL results.

3. Substrate: 285nm SiO2/Si. Other substrates are available upon requests, such as 100nm SiO2/Si.

4. Larger sizes can be customized. If you have special requests, please contact: sales@6carbon.com

Customization

MoS2 on optical quartz, flexible PET, PDMS, silicon wafer and so on are also provided. Sample size can be customized. Contact sales@6carbon.com and tell us your requirements.

Lead time

In stock. Lead time: 1~3 business days.

Introduction

Molybdenum Disulfide (MoS2) is graphene-like 2D material. One obvious difference with graphene is that MoS2 has a bandgap. Monolayer MoS2 Film is a semiconductor with a direct bandgap of ~1.8eV, while Bilayer or multilayer MoS2 film is has an indirect bandgap decreasing to 1.2eV with layer increase.

6Carbon MoS2 film is produced with chemical vapor deposition (CVD) method, depositing monolayer or multilayer MoS2 Films on various substrates, such as SiO2/Si wafer, Silicon wafer,optical quartz plate,mica, sapphire and so on. We also supply customized MoS2 products based on customers' requirements or design.

Application

MoS2 films are mainly used in optoelectronics fields.